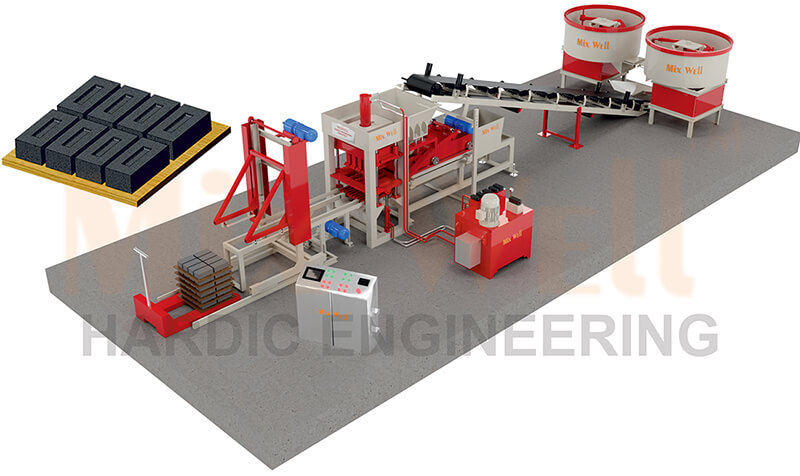

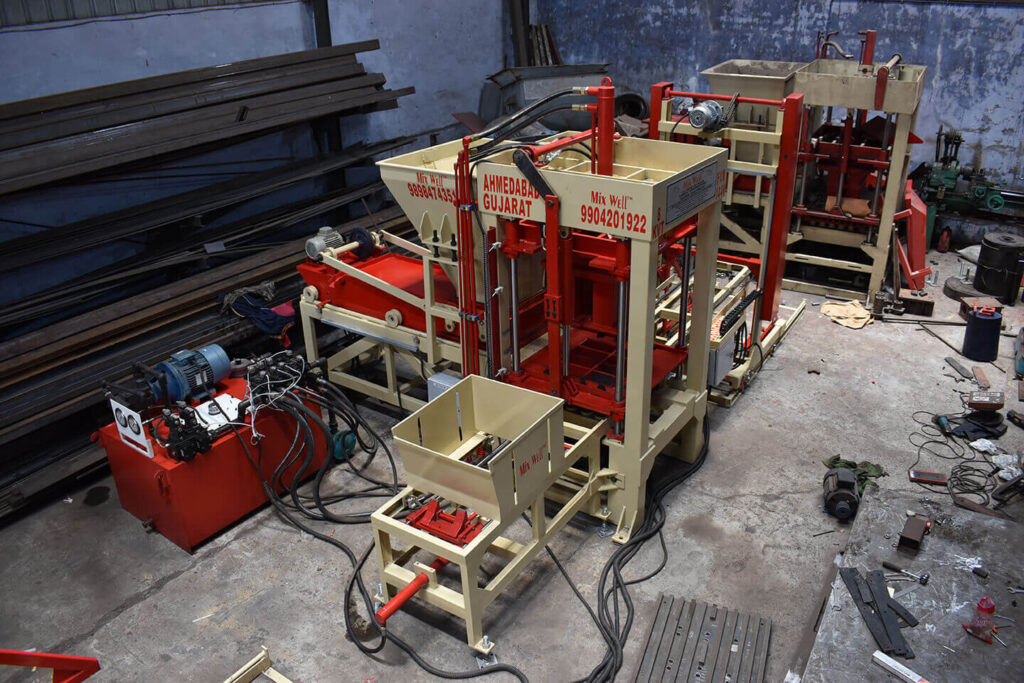

A Paver block making machine is a specially designed machinery to manufacture interlocking bricks, paver blocks, and concrete blocks. These blocks are utilized in many different building projects, including driveways, walkways, and pavements. This machinery increases output, reduces human error, and elevates the overall quality of the blocks by automating the production process. Brick Machinery is top paver block making machine manufacturers to made machine with reliability and accuracy. To maximize productivity and ensure excellent manufacturing they use the newest technology.

How to Increase Efficiency by a Paver Block Making Machine!

In the field of construction, with the goal of increasing productivity and efficiency, Technology is advancing quickly. The Paver block making machine is an essential instrument that is modernizing the production of Paver blocks and is one of the greatest innovations. Leading the way in this revolution is Brick Machinery, an Indian paver block making machine manufacturers.

Important Features of Paver Block Making Machinery

Increase in Production Capacity: The large production capacity of Paver block-making machinery is one of the key features. These devices have a daily production capacity of thousands of blocks depending on the model. Due to their high productivity, construction companies can fulfill deadlines and increase profits by shortening production times.

Automated and Easy of Use: The Paver block making Machine is good for both small and large-scale enterprises, as these devices include excellent automation, which greatly reduces the need for manual labor. To supervise production their control panels are easy to use and require little training for operators.

Prefect Moulding: Modern molds on Paver block making machines make sure the blocks are produced with uniform sizes and shapes resulting in a high-quality final product.

Sturdy Design: In the most demanding operating environments, Premium materials are used to construct these machines to guarantee durability and strength. They can last years of dependable performance in industrial environments where they are often used with very little upkeep required.

Energy Efficiency: While producing large amounts of work, energy efficiency is even more significant. Paver block making machines are engineered to use less energy without sacrificing performance hence resulting in low operating costs.

Low maintenance: The design of these machines focuses on reducing instability. There is no interference to production due to their easy maintenance, and easily available parts.

Benefits of Paver Block making machine:

An efficient paver block making Machine increases productivity. Paver block making machines enable the automation of labor-intensive and time-consuming manual manufacturing processes allowing for the production of huge volumes in a shorter amount of time. Construction projects are completed more quickly as a result of this increase in productivity.

Stability is important in any construction project. Construction companies may guarantee consistency in size, shape, and density for every block produced by utilizing paver block making Machinery. Using manual techniques, It is difficult to attain this degree of quality control.

paver block making machine manufacturers significantly reduce material waste because they require minimal manual work and exact measurement. The economical use of material, sand, and cement ensures the precision and consistency of every batch produced at a reduced cost with favorable environmental benefits.

For large-scale projects in particular, labor expenditures can be a major expenditure when producing blocks by hand. Through process automation, businesses can reduce labor expenses while preserving high output levels. Because only a few people are needed to operate paver block making machines, so labor costs are significantly reduced.

The paver block making machines are designed to consume less energy, reduce material wastage, and create eco-friendly products that align with sustainable construction practices. This is particularly beneficial in today’s market, where eco-friendly solutions are in demand.

Assurance of Quality for Paver Block making Machine

If you are investing in quality you need to select a paver block making machine rather than just purchasing machinery. Before it is delivered to the customer, each machine is extensively tested for functionality, dependability, and efficiency. The Paver block-making machine is an outstanding craftsmanship.

Brick Machinery offers complete guidance for Paver block making machines in addition to high-quality machinery. The team of experts is on hand to help with installation, operation, and maintenance, to ensure that Paver block-making machine continues to operate at its peak for many years.